Bioenergy & Renewable Natural Gas

Enscope has joined forces with leading German technology provider Weltec Biopower to provide proven and reliable solutions to the Australian Bioenergy market.

Green energy from renewable organic sources has huge opportunity in Australia.

Whether your interest is driven by turning an organic waste disposal cost into an energy revenue stream, demand for energy (gas, power, heating & cooling), reduction of greenhouse emissions or a combination of all of these, WE can develop the right solution.

As the global energy focus changes, we are proud to continue supporting traditional long-term clients as well as building new relationships in new markets and regions.

Weltec and Enscope have a history of successful project delivery in the Energy and BioGas sectors globally for over 20 years.

We are outcome-focused and look forward to working with you to achieve your goals on your next BioGas project.

THE PARTNERSHIP YOU NEED FOR

PROJECT SUCCESS

…AND HOW WE CAN PROVIDE IT

WE ARE

COST EFFECTIVE

WE work with our clients to develop optimum solutions based on their unique requirements, feedstock and gas

compositions. WE can provide power, gas, heating and cooling options to maximise energy efficiency. WE only proceed with projects that we know will meet our clients’ expectations.

WE PROVIDE

100% RENEWABLE

ENERGY SOLUTIONS

Energy generated by Anaerobic Digestion of organic materials is 100% green, and part of the circular economy. In many cases such energy sources are a net greenhouse reduction, capturing methane that would otherwise be naturally released to the atmosphere by organic decomposition.

WE ARE

SAFE

With Weltec’s enviable 20 year history

in bioenergy developments globally and

Enscope’s wealth of experience in gas and energy developments in Australia and beyond, you can be sure that the plant will meet high standards of process and operational safety.

WE ARE

SCALABLE

Using modular technology, WE can provide an optimum solution to any organic material or biogas processing volumes, and can provide for multi-stage expansion of the plant where future growth is anticipated.

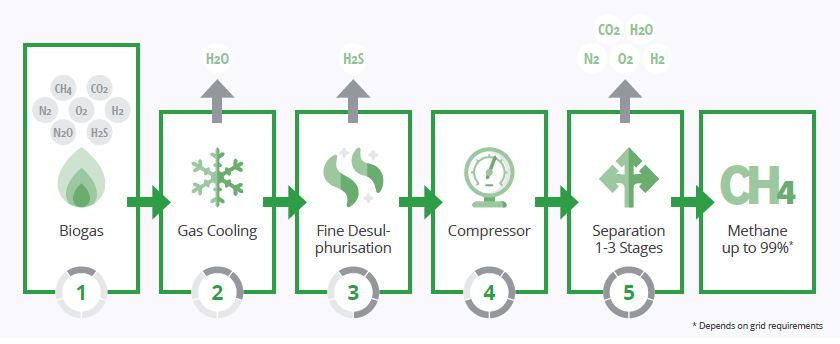

BIOGAS UPGRADING TO RNG with membrane technology

EASY AND FLEXIBLE GAS PROCESSING

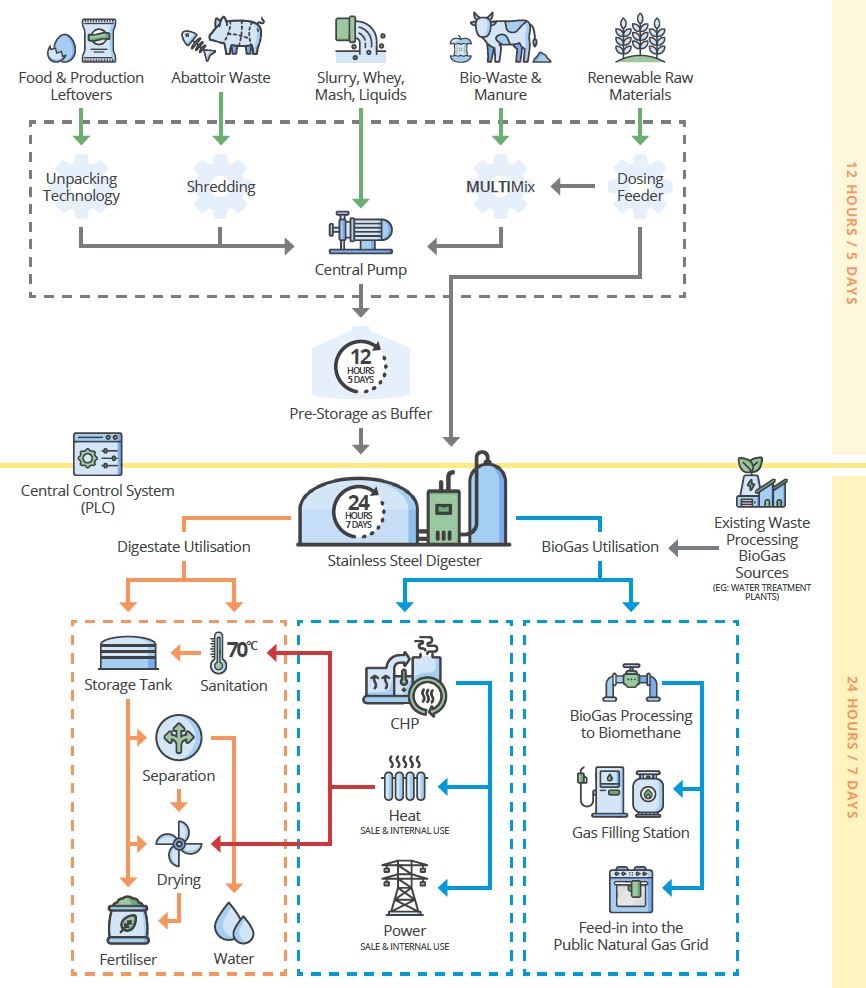

In the first stage of biogas processing, the biogas is pre-dried, scrubbed and desulphurised with active carbon. Before the actual gas separation process takes place, the gas must be compressed to 8-15 bar.

Subsequently, the CO2 and water vapour are separated from the methane. Special polymer membranes through which the raw gas is forced have been developed for this process stage. The membranes are able to separate the CO2, H2O and CH4 molecules due to their different sizes and solution behaviours. For instance, CO2 molecules are smaller than methane and pass through the micro-pores of the membranes faster than methane.

The three-stage separation of WELTEC BIOPOWER can reduce the methane slip to less than 0.5 percent.

BENEFITS

– Methane yield of up to 99 percent through multi-stage procedure

– Intelligent control ensures uninterrupted gas feed-in

– Extremely high plant availability & low maintenance overhead thanks to durable membranes

– Easy to operate

– Modular structure enables extensions

– Quick installation thanks to compact container setup

– Separation of the molecules without any additional aids such as chemicals or water

– Separation without any further need for heat

– No downstream dryer required

– Feed-in into the natural gas grid possible in some applications without additional compression

These benefits mean low plant and operating costs!

BIOGAS PRODUCTION and utilisation process